In recent years, Framo has invested heavily in the use of VR technology for sales and trade fairs, and now this is being taken a step further.

Using virtual reality (VR) opens up new opportunities within teaching and instruction, and can make the training more realistic and engaging.

“Recent events have underlined the need for platforms that enable teaching and training to take place wherever you are, without meeting face to face,” says Gaute Flatøy, Framo’s Training Manager.

Framo is leading a new VR project. Together with NagellD, the maritime apprentice training office, Maritime Bergen and Bergen Maritime upper-secondary school, we are developing educational content and simultaneously moving over to newer VR solutions with a wider area of use.

The new technology involves computers and sensors integrated into the VR glasses, eliminating the need for an external PC and cables.

“This VR technology makes it easier to carry out practical exercises with a group. Multiple participants can operate in the same world, even though they’re in different places,” says Flatøy.

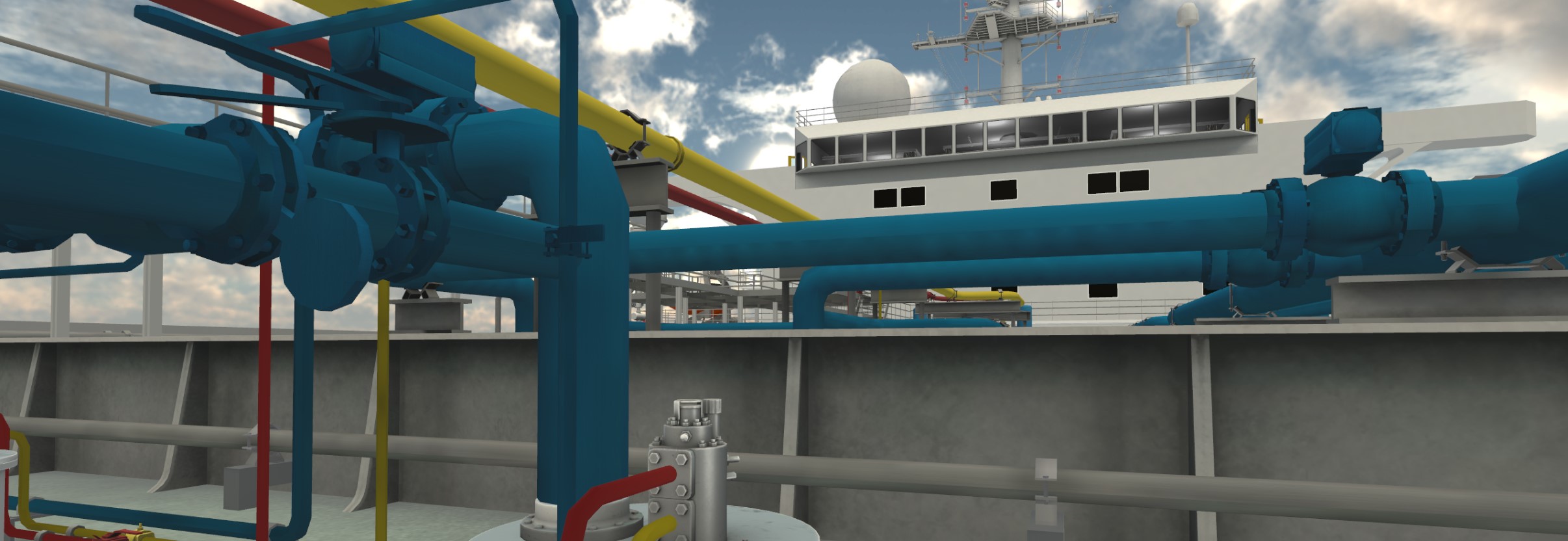

The tool, which combines e-learning and practical exercises wearing VR glasses, will be used to develop expertise among both customers and our own employees. It will also be shared with maritime upper-secondary schools in Western Norway, as an exciting and instructive visual teaching programme. The technology enables students to “experience” a chemicals tanker and see how it is constructed and works – something that technical instructor Reidar Gjesdal at Bergen Maritime upper-secondary school is excited about. He is an expert in hydraulic pumps and has spent several decades teaching both Framo employees and students.

“From a teaching perspective, using VR technology is a massive benefit – particularly when it comes to a subject like hydraulics, which is so abstract. It can show what is happening and make the subject more interesting. Usually, when you look at a pipe, all you see is the pipe, and it’s inert. It’s difficult to envisage an oil flow, but this is where the VR technology can help,” Gjesdal explains.

“Being able to take the pumps apart and put them together again, visualise the balance between hydraulic motors and centrifugal pumps, and get an idea of what’s happening inside the pipes is priceless too. Simply grasping output and efficiency and gaining a greater understanding of general physics is a big benefit. I think we’ll get more people interested in the subject by visualising it with VR.”

Gaute Flatøy in Training also agrees that VR’s big advantage is it can be used to create realistic scenarios. This makes it possible to carry out practical drills for high-risk work in safe surroundings. The opportunity of extensive practice also improves safety.

“In the virtual world, we can train for unforeseen events that hopefully will never happen, gaining invaluable experience in case you suddenly find yourself in such a situation. What’s more, VR technology provides such realistic experiences that it has a big impact when it comes to drilling routines,” says Flatøy.