Framo submersible pumps at the core

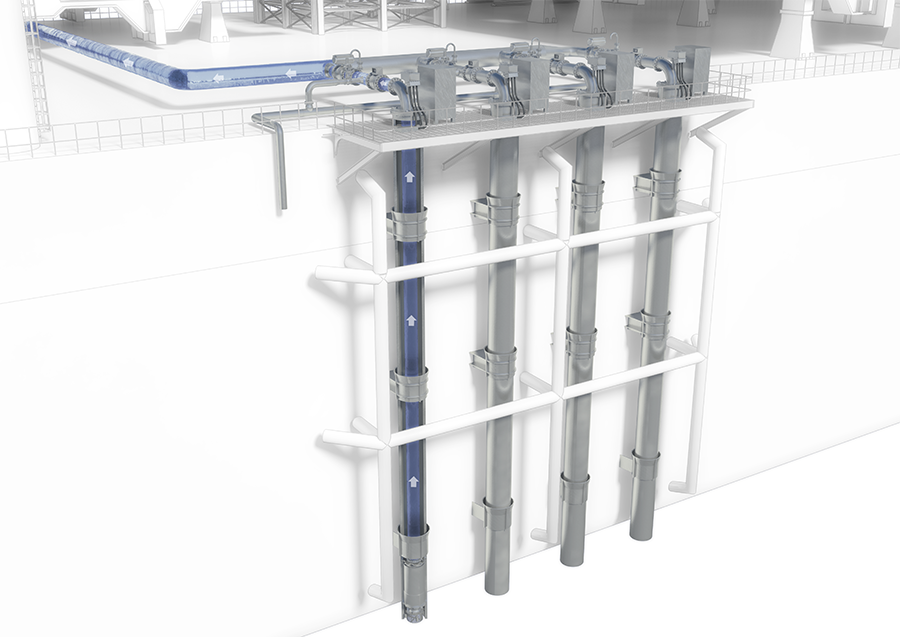

Framo submersible pump technology has improved business at sea for over fifty years. The revolution that began with our unique hydraulic pumps continues with our cable-free electric submersible pumps, which lie at the heart of most oil and gas applications.

No submerged penetrations

An intact hull means a higher degree of safety. The unique Framo cable-free concept eliminates the concerns associated with electric submersible pumps, such as submerged cable penetrations and the hassles of cable handling.

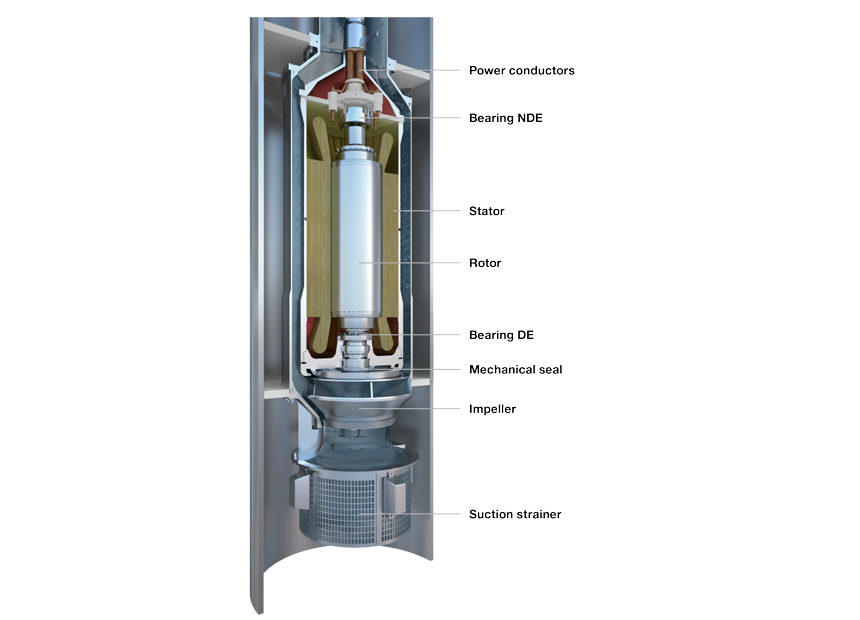

In the Framo cable-free concept, the electric submersible pump is suspended from a riser pipe containing a built-in transmission system for the electrical power. The pump itself is an end-suction centrifugal pump, driven by an integrated oil-filled induction motor designed for direct on-line start (DOL) or variable-speed drive (VSD) operation.

Continuous condition monitoring

The finished pumping system is insulated, cooled and lubricated by a small external oil circulation unit, which creates an internal overpressure that prevents any ingress. The double sealing system further ensures that no oil is leaked to the seawater side via the conductor system. The external circulation unit also continuously monitors the condition of the submerged pump/motor, providing information about temperature, pressure, cleanliness and seal integrity to the control system.

In brief:

The Framo cable-free concept is certified for hazardous areas and means:

- End suction to ensure maximum NPSH (net positive suction head) availability

- No submerged penetrations or cable handling

- Built-in power transmission Stiff shaft operating below first critical speed, ensuring low vibration levels

- Ingress protection through overpressure

- Compact, low-weight design

- Simple and easy installation

- Condition monitoring

Protected and integrated power

The unique Framo riser system offers mechanical protection while eliminating electrical cables and their disadvantages. Flanged at both ends, the riser pipe sections contain a built-in cooling system and three power conductors spaced by insulation pieces.

When the riser pipe sections are stacked, spring-loaded sliding connectors on the conductors create a safe and reliable electrical connection. The oil pipe sections are fitted with connectors, and the flanges are bolted together to complete the assembly.

Oil and gas puming systems

Technical brochures

Stay updated

Contact form

Contact us for more information

Thank you for contacting us

We will get back to you as soon as possible