Framo, Maritime Partner, Norbit Aptomar and NorLense have formed the OSRV (Oil Spill Recovery Vessel) Group to offer a comprehensive oil spill response service.

- Our aim is to be a one-stop-shop where we pool our efforts and act as a total systems supplier of safe, highly functional, and well-tested technology.The emergency response equipment has undergone thorough testing and quality assurance drawing on 40 years of oil spill response experience, says Jørgen Brandt Theodorsen, Area Manager, Oil & Gas Pumping Systems, at Framo.

- OSRV offers a package solution that covers everything the customer needs – from detection and containment to recovery of the spill. All conducted with reliable equipment that can handle the challenges if an accident occurs.

Framo, Maritime Partner, Norbit Aptomar, and NorLense have come together to establish the group OSRV (Oil Spill Recovery Vessel) – a “one-stop-shop” for oil spill response. The companies in this Norwegian cluster are all specialists in their particular fields. OSRV is a solution bringing world-leading technologies together. All the Norwegian-manufactured components have a dedicated function to achieve the best result possible. This also allows for conventional supply vessels to be converted to emergency oil-spill response support units.

All the technology just one phone call away

- The customer only has to deal with one of the partners to get access to a complete system that covers everything from A to Z and is fully adapted in terms of functionality, volume, and size, says Roy Arne Nilsen from the international sales team at NorLense.

This is well-proven equipment that is in use world-wide. Every year, the technology is tested using real oil during the oil-on-water exercise conducted by the Norwegian Clean Seas Association for Operating Companies (NOFO).

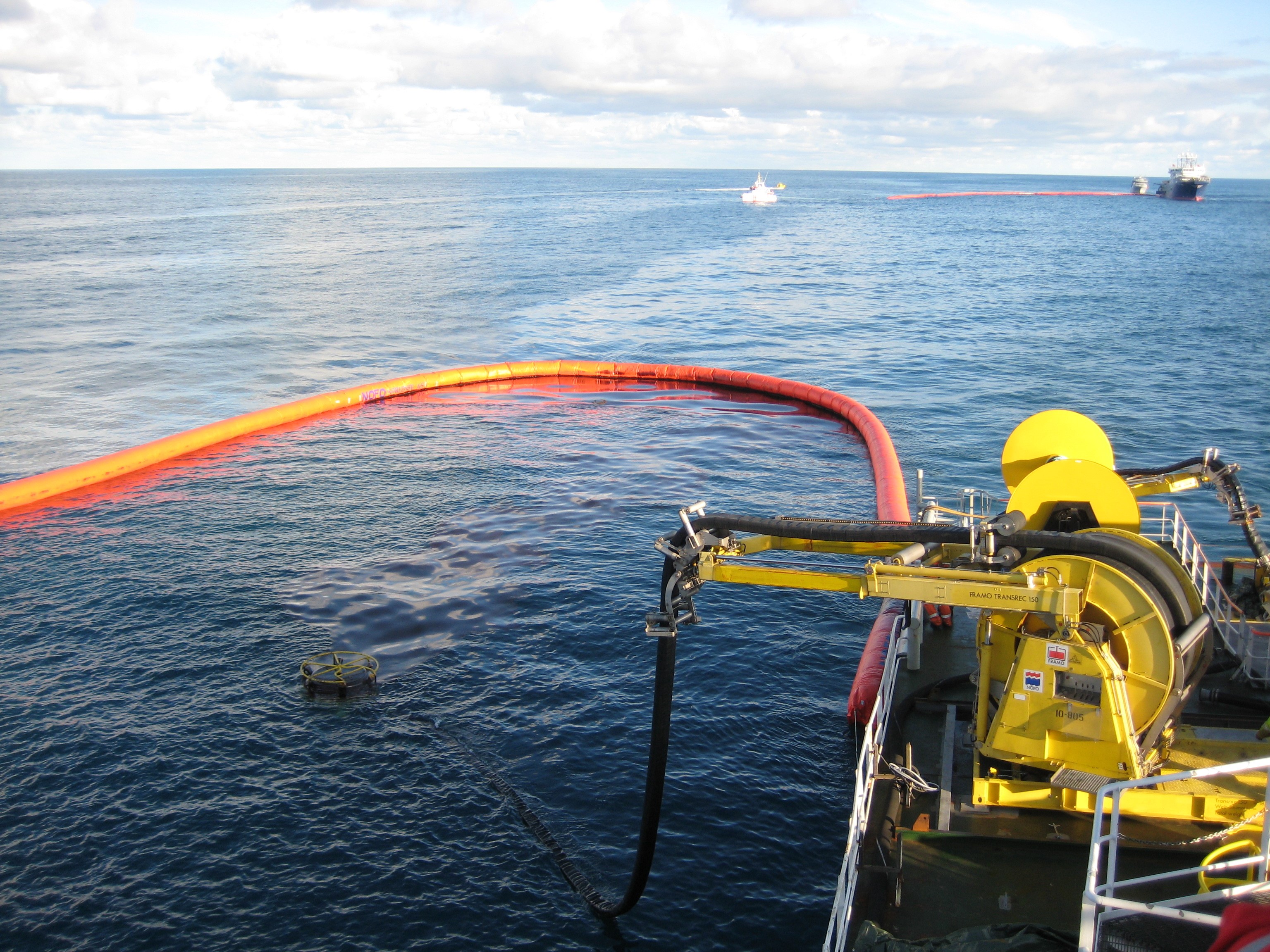

Aptomar’s radar can identify and produce an overview of the oil slick, whereas Maritime Partner's powerful, high-speed vessels are perfect for pulling equipment such as booms in place. The oil is contained with booms from NorLense, and is then recovered onto a vessel with the Framo TransRec Oil Skimmer System.

Improved utilisation of laid-up tonnage

The market for emergency oil-spill response expanded in step with the oil production – until the oil crisis hit. Reduced activity levels in the oil industry also caused an abrupt downturn in shipbuilding, and have sent hundreds of offshore vessels to quay without assignments.

However, the market is again gathering pace.

When the oil crisis hit, OSRV Group had already delivered the oil spill response solution to over 30 vessels in Brazil alone, and this has provided invaluable insight into how the various systems best interact.

- With our package solution, supply vessels can easily be upgraded and used as part of new emergency response tenders. It is quick and easy for shipowners to convert existing vessels in order to offer new services to oil companies, says Lars Solberg, Sales and Marketing Director at Norbit Aptomar AS.

There has also been an increased focus on costs. Projects are adapted to suit a lower oil price.

– We notice that customers are more conscious that the solutions in which they invest must be robust, and that there are no surprises in terms of maintenance costs, continues Solberg.

Short lead-time on delivery

Going forward, delivery lead-times will be of utmost importance.

– When the assignments start ticking in, getting the mandatory equipment on board could for many become a time-critical issue. At OSVR Group, we will ensure that an emergency oil-spill response system is put in place in time, says Peder Myklebust, Managing Director at the boat-building specialist Maritime Partner.

By using OSRV Group, the operator is just one phone call away from a complete solution delivered at the right time.

- We operate with a delivery lead-time of a mere 8 weeks for the full package of Norwegian-manufactured, high-quality equipment.

Close dialogue and collaboration between the four manufacturers leave customers with first-class support and quality assurance at every level.

- Oil spill response is a complex operation, emphasises Solberg from Aptomar.

- This is a turnkey solution where customers have access to emergency preparedness expertise without themselves having to acquire this. Shipowner receive a complete system tailored to meet mandatory requirements, and can focus on their contracts and assignments instead.

User-friendly

Handling of the equipment requires minimal manpower.

This reduces the need for crew members, is cost-effective for the shipowner, and increases the safety level as there are fewer people involved. Thorough training of operators helps extend the lifespan of the equipment.

- When an accident occurs, oil recovery is a race against the clock. The sooner a spill is detected, the sooner it can be contained and managed. It will then be cheaper and safer to recover the spill as quickly as possible, says Jørgen Brandt Theodorsen from Framo.

In the event of an oil spill, Aptomar's radar performs the difficult initial task of detecting the spill on the surface of the sea. Live data from the infrared sensor technology establish the location of the oil slick, its size, and in what direction it is heading. This provides an overview of the operation and helps decide where to navigate the vessel tasked with the deployment of booms.

In 20 minutes, one person alone deploys 400 metres of the world’s largest oil spill containment booms.

The offshore booms from NorLense are designed to handle demanding challenges at sea, and Maritime Partner’s high-speed vessels will smoothly and quickly pull the booms into the correct formation to achieve the best containment result possible. Everything is then ready for the Framo recovery system to start the pumps that have the capacity to clean the ocean for up to 400 000 litres of oil per hour – equivalent to 16 large road tankers being emptied of their cargo in 60 minutes.

Such capacity is paramount in the event of an oil-well blowout – when every minute counts. Water and oil expand when mixed. Similar to a fire, a small oil slick can grow very large if not dealt with at an early stage. This may result in significant costs and environmental damage.

To avoid that valuable oil recovery time is lost when the supply vessel is full, a tanker can be called in and the oil transferred via Framo’s TransRec system. This also prevents the operation from being interrupted.

Icy and dark conditions are not a challenge either.

- With increased activity in the north and complete darkness for half the year, it is paramount that our equipment operates as well during night time as in daylight, says Theodorsen.

.