A new system shows the status of Framo’s offshore pumps in real-time. With a full overview of offshore pumps in operation, everything is in place for even more efficient operations for customers.

- We have been online with this system for three to four years now, and we have come the furthest with Aker BP which now shares all pump information with us in the cloud. Aker BP has been very visionary and eager to make this happen, says Johan Lunde Sagen, pump specialist and link between the various groups in the development project.

Real-time

The new system is built up of advanced algorithms and sensor data and provides access to all technical information about the pumps in real time. Data is sent from the field to shore, where Framo's project engineers can form an opinion about the condition of the pumps and how they are operated and implement measures if necessary.

- How the operators operate the equipment can have a major impact on both efficiency and service life. If our system tells us that a pump is not operated appropriately, we can make suggestions on how it can be improved, says Bjarte Thilesen who is the project engineer responsible for Aker BP's installations at Framo. For example, it is becoming more and more relevant that the equipment should use as little energy as possible in operation, and here we can provide advice and guidance, he adds.

Predictable

At the same time, the data from the system also makes it possible to identify conditions that are not as they should be. Changes can be tracked from day to day, and variations can be indications that something is not working satisfactorily. For the operators, the new system creates value in the form of higher regularity and better predictability in operations. It can eliminate downtime, increase production, and eliminate non-value-added steps in work processes. For Framo, it also provides better opportunities to plan efficient maintenance.

- With the new system, we can both contribute to the equipment being operated in the best possible way and identify and fix faults quickly. If, contrary to expectations, a fault should occur on one of the seawater lift pumps we have delivered, which is used to cool the systems on board, we can familiarize ourselves with the course of events, give instructions to the operators offshore and fix things quickly. Our joint (together with the operators) ability to operate the equipment in the best possible way and identify and correct any faults quickly, can have an impact on production, and in the oil industry it can quickly become a matter of great values if production is reduced, says Johan.

Work well

Together with colleague and computer engineer Rogerio Povoa, he notices a growing interest in remote monitoring both on the Norwegian continental shelf and from operators all over the world. The interest has been there for a long time, but the pandemic has also been a catalyst. The SMART contract Framo has entered with Aker BP means that Framo will be paid for the systems' availability and performance. Such performance-based contracts are becoming more and more common, and Framo wants to be able to offer remote monitoring in real time to other customers as well.

- For us, this system is an important tool in maintaining our status as the pump supplier that delivers the most reliable pumping systems and the best customer experience. Last year, Aker BP chose to almost double the number of pumps that are covered by this contract, and that is probably an indication that it works well, says Rogerio.

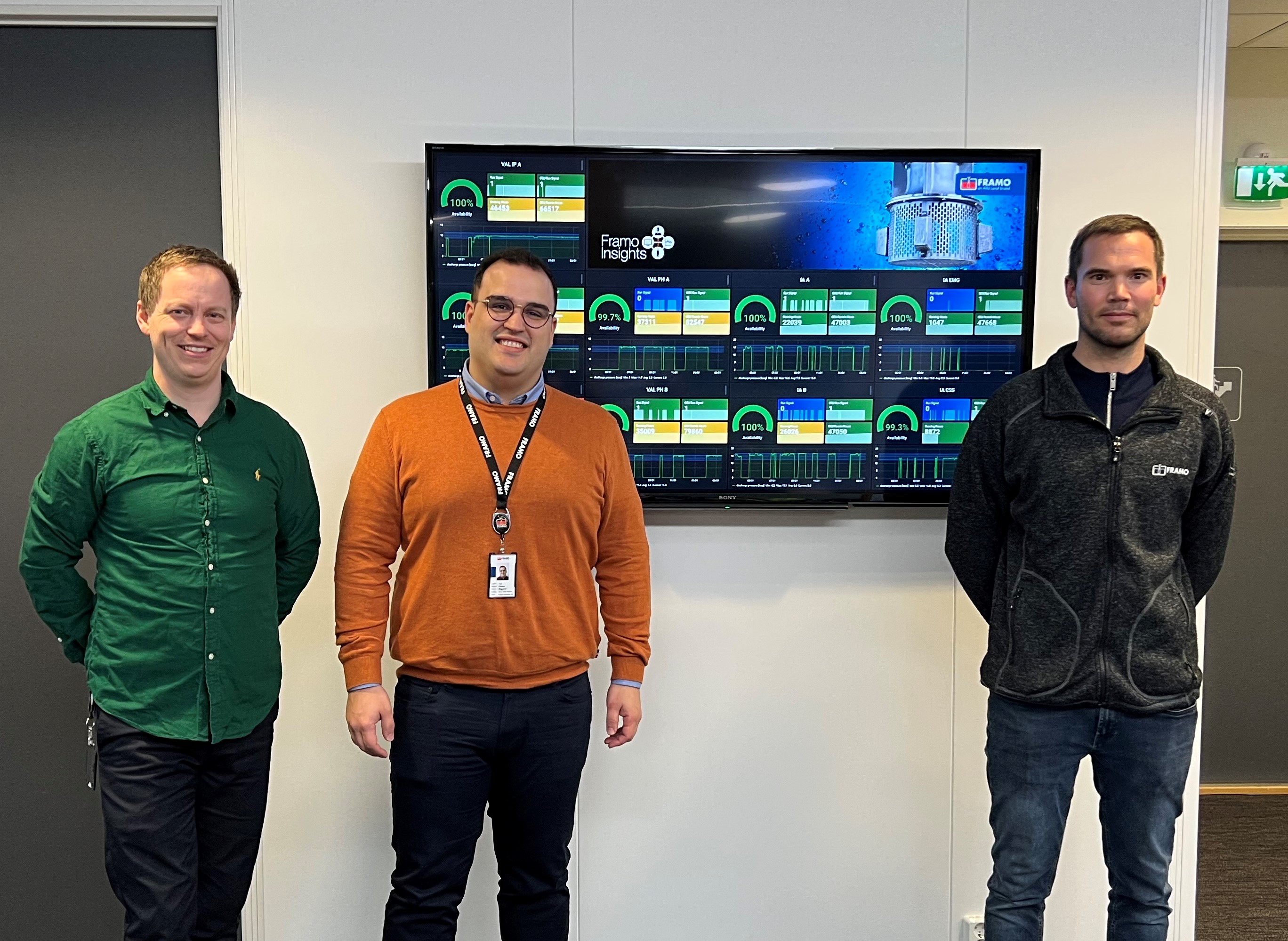

From the leftt: Johan Lunde Sagen, Key Account & IO, Rogerio Povoa, Data Analysis Engineer, and Bjarte Thilesen, Project Engineer - all Framo Services AS.

From the leftt: Johan Lunde Sagen, Key Account & IO, Rogerio Povoa, Data Analysis Engineer, and Bjarte Thilesen, Project Engineer - all Framo Services AS.