1. Designed for efficient discharge

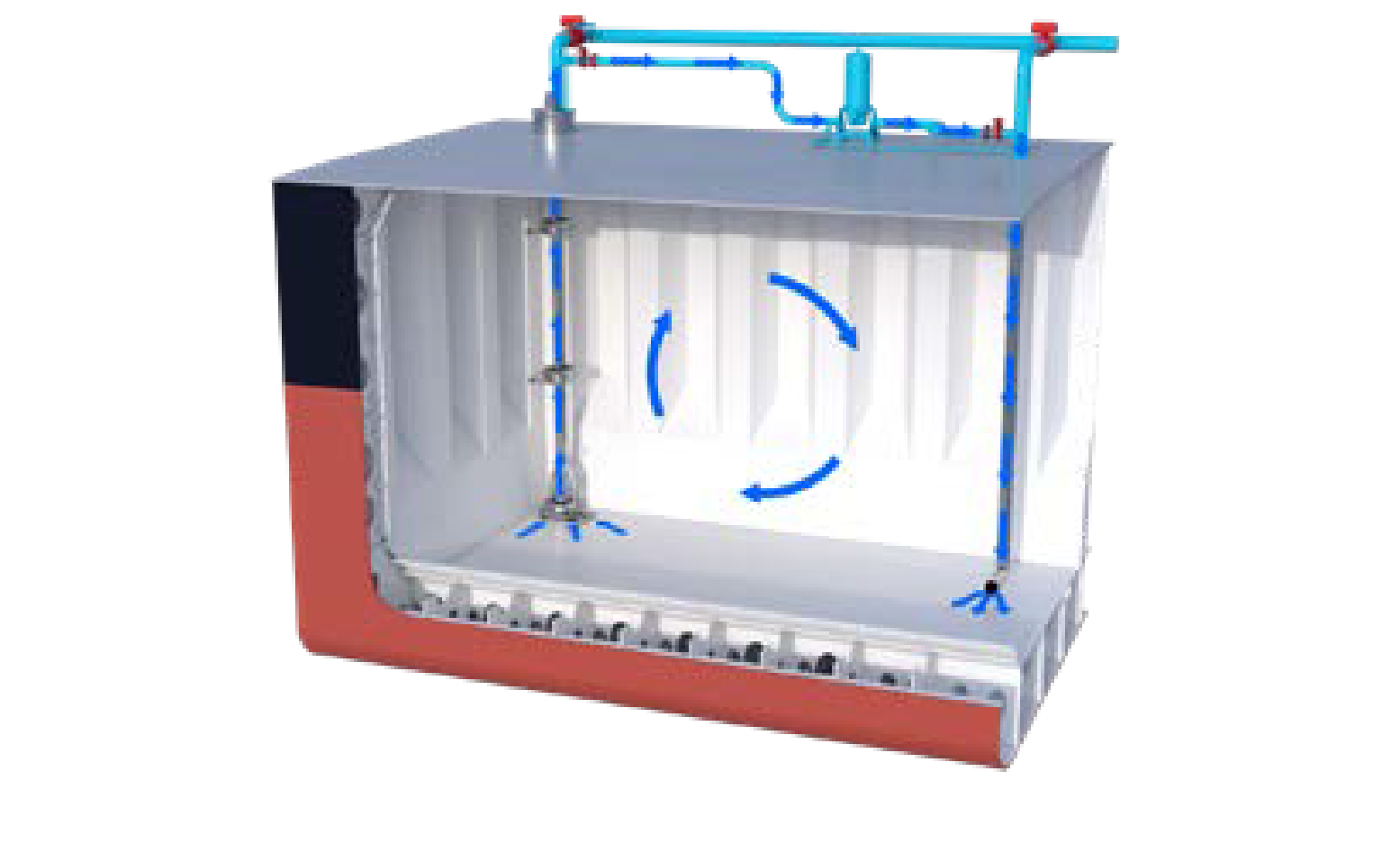

The submerged cargo pump takes suction directly from the bottom of the cargo tank. The design eliminates the need for long suction lines and submerged cargo valves inside the tanks. As a result, full discharge capacity can be maintained from the start to the very end of the discharge operation without any risk of cavitation. With one pump in each tank, complete cargo segregation is achieved, eliminating the risk of contamination between cargo tanks.

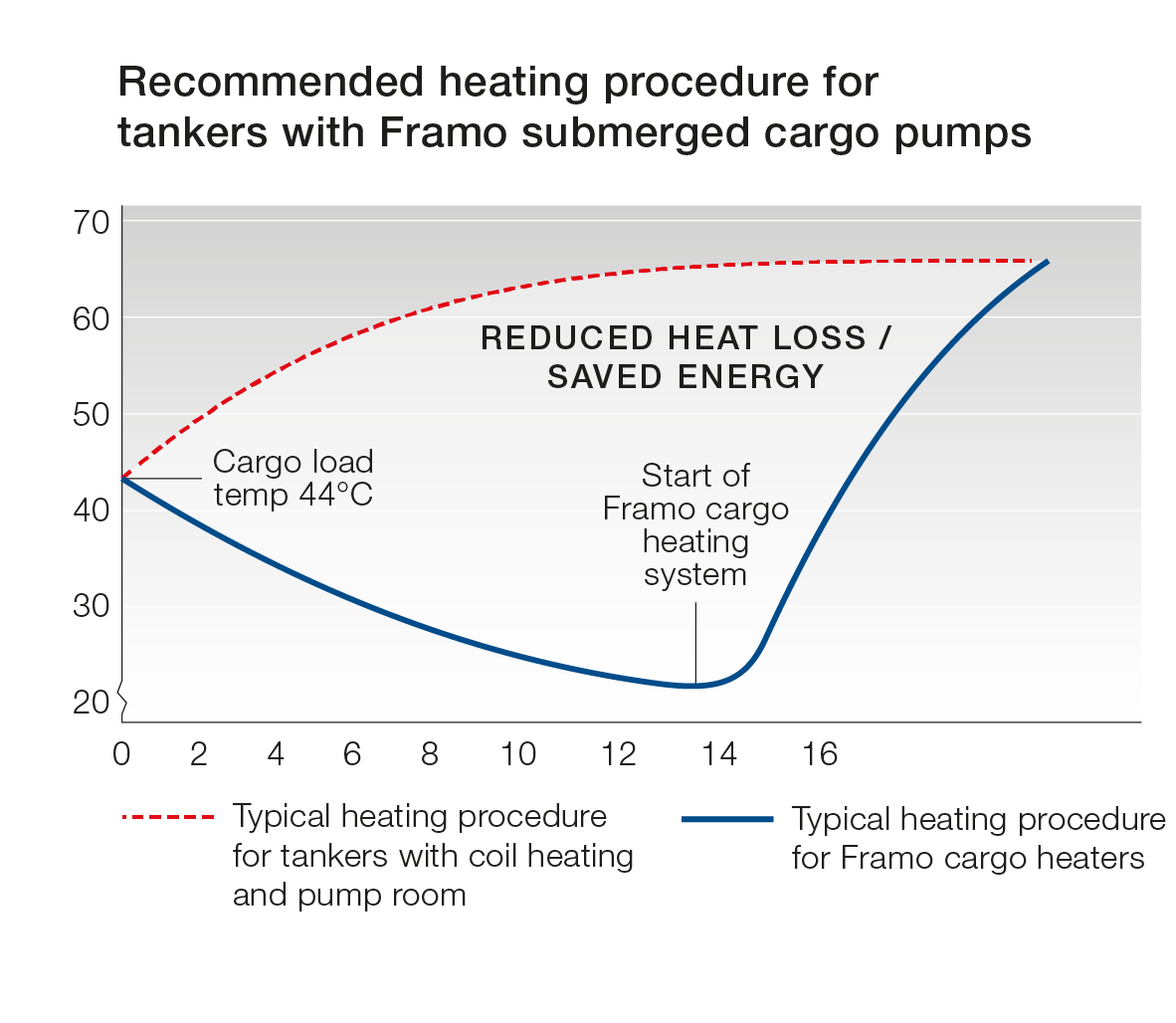

2. Energy-efficient cargo heating

During a 20-day voyage with heated cargo, Framo deck-mounted cargo heaters can save a total of up to 60 metric tons of fuel. The heaters allow a higher temperature drop at the beginning of the voyage, then raise the cargo temperature before arrival in the discharge port. The Framo system heats and circulates cargo to create a turbulent flow over the heater which improves heating efficiency. This shortens the heating period towards the end of the voyage.

Framo heat exchangers provide flexibility to heat all traded cargoes, such as heavy fuel oils, oil products, and palm oils, as well as chemicals that may be temperature-sensitive, requiring more gentle heating. The heating medium can be saturated steam, hot water, or thermal oil.

3. Fuel savings and environmental footprint

The Framo cargo pumping system can save up to 80%, or 40 metric tons of fuel per cargo discharge, compared to conventional steam-driven pump room solutions. With Framo deck-mounted cargo heaters, an additional 60 tons of fuel can be saved on a 20-day voyage

4. Enabling more storage space

With the cargo pumps submerged inside the cargo tanks, and ballast pumps inside double-side ballast tanks, there is no need for a pump room. Eliminating the pump room can add up to 2,000 m3 of valuable storage volume to the vessel. A 2% increase in cargo carrying volume can be achieved, as well as an increase in the overall safety level, as the pump room represents a hazardous area.

5. Reduced number of boilers

Only one boiler is needed since the steam-driven turbines can be removed. A 30-ton boiler is sufficient for cargo heating and tank cleaning.

6. Simplified piping maintenance

With cargo piping running on deck, where it is easier to inspect and maintain, there is 60% savings in piping and valves. The simplified cargo piping system is much easier to drain and strip.

7. Increased cargo flexibility

Efficient cargo switches are made possible by the built-in stripping device – as little as 60 litres of cargo remaining in the tank.

8. Fewer ballast voyages

Facilitating an efficient and easier switch between different grades of cargoes increases opportunities for triangulation, with less time in ballast.

Contact Us

Framo Cargo Pumping System for Aframax

Stay updated

Contact form

Contact us for more information

Thank you for contacting us

We will get back to you as soon as possible