Safe operation

Dangerous chemicals, acids, oils and edibles must be handled in a safe way for people and environment. The tanker must be equipped with cargo pumps that can efficiently empty cargo tanks and associated cargo piping to meet the most stringent requirements, and withstand the though impact during hours of tank cleaning afterwards. Switch between cargoes without cargo contamination. Carry anything from acids to drinking water.

Framo cargo pump is designed for any cargo temperature prevailing in tankers. The pump is continuosly temperature controlled by the circulating hydraulic drive oil.

The Framo cargo seal arrangement is exposed to static cargo tank pressure only.

Optimal operating conditions are maintained at all pumping conditions. Volatile or heat sensitive cargos can be discharged efficiently in a safe manner.

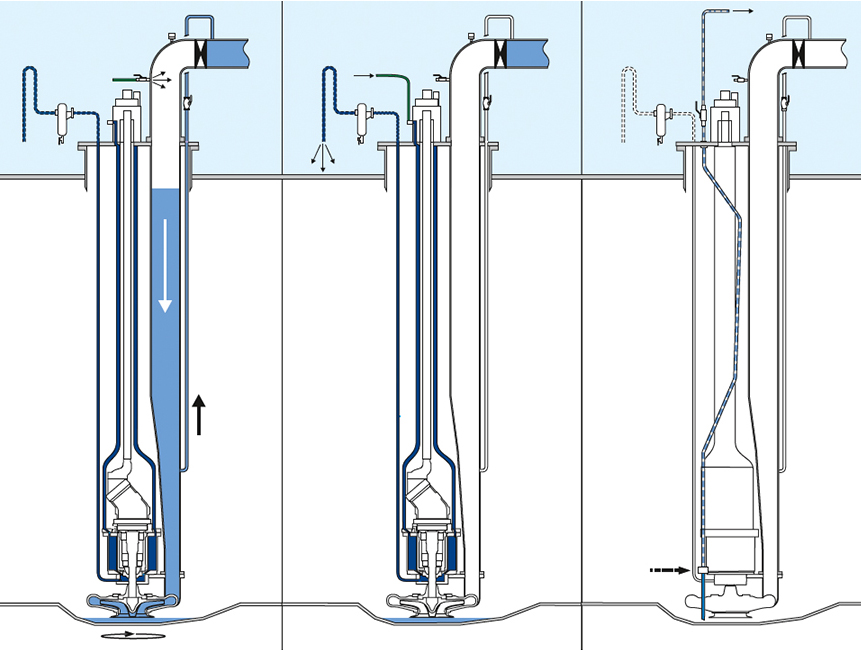

Stripping (left image)

When the cargo tank is empty, the speed of the cargo pump is reduced to perform the final stripping of tank:

- Close the cargo valve.

- Open the small ball valve on the stripping line.

- Pressurize the pipe stack by connecting the purging hose with compressed air or nitrogen.

- Press cargo out through the stripping line and into the cargo line.

The pump impeller rotates and acts as a non-return valve to prevent cargo from returning back to tank.

Purging and seal monitoring from deck level (center image)

The pump’s cofferdam is purged before and after discharge operation. Any leakage across the cargo seals or hydraulic oil seals collected in the cofferdam, will be forced to the exhaust trap on deck where it can be measured.

This is a simple and reliable seal condition monitoring system. No need for any electric sensors nor any automatic control system.

Vacuum drain (right image)

The standard Framo cargo pump design meets all applicable rules for stripping under the IMO Annex II requirements.

However, as an option, the Framo cargo pump can be equipped with a vacuum drain line that will empty suction well completely and allow for a dry tank top and quick re-loading of cargo.

Contact Us

Marine Brochures